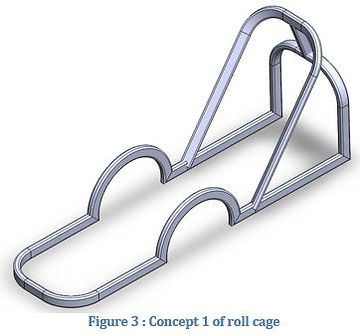

Concept 1

An initial idea was to create a roll cage that would provide safety to the rider and become a surface for shell attachment. This concept would follow the curvature of the seat and have rectangular rod manufactured using foam and carbon fiber running along the curvature of the shell. As seen in Figure 3, the rectangular rods also follow the contour of the front to wheels to prevent obstructing the wheels when the vehicle is turning.

Concept 2

The second concept was taken from concept 1. In this concept, the front portion of the roll cage in concept 1 was removed as shown in Figure 4. The purpose of this concept was to saves weight and material that is needed for the frame. The trike needs to be the lightest as possible without sacrificing the strength. This would allow the trike to travel faster.

Concept 3:

The final concept is very simple. The concept of the roll cage is vertical placed near the shoulder area of an average rider. This concept requires the least manufacturing among the concepts discussed for the roll cage. It would also cost less to manufacture and weighs less. Figure 5 shows the front view of the concept 3.

Evaluation of Roll cage designs:

A list of 4 deign attributes was created and then weight according to the project’s goals and requirements. Each attribute will be measure from a scale of 1-10. The weight factor scale is 1-5 where 5 represents the most important attribute for the project. The first design attribute is manufacturability, which is how difficult is the product to manufacture. Cost attribute represents the material and manufacturing cost for each concept. The shell attachment attribute represents the ease of attaching the shell to the roll cage. Each of the design attribute was given an un-weighted score on a scale of 1-to-10 with 10 being the best mark. The scores were then multiplied by the weight factor for the corresponding attribute.

Concept 3 earned the highest score according to Table 1. This led to the concept 3 as the final concept. This concept will be manufactured out of carbon fiber. The roll cage will be places just about the shoulder area of an average person as shown in Figure 6. There would be a cutout in the frame where roll cage will be fitted. After placing the roll cage, extra layers of carbon fiber would be wrapped around the area to provide strength to the area.